|

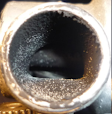

| Dirty Valve |

|

| Cleaned Valve |

|

| ICV Ele. Connection |

Cleaning the airflow sensor - if not done in the last 60K miles or so.

It must be cleaned with a Q-tip in conjunction with “CRC Mass Air Flow Sensor Cleaner” just spraying it out will not always release the grey debris coating that has accumulated on the sensor element, the element when clean looks like a white circuit board with visible components on it. See Appendix “M” “Mass Air Flow Sensor MAF Cleaning does it work?”. If the sensor is throwing an OBD Code or is suspect for other reasons and the sensor element looks clean, cleaning it will not improve its functionality, it may just need to be replaced. Also see the section titled " The mercurial fuel delivery system in a 993 engine, " at the bottom of this page

Fixing insidious, power-robbing, vacuum leaks – When one of the vacuum actuators, three on the non-Varioram and five on Varioram Cars, or any of the rubber hose connectors fail (leaks) or slips off the intake on a Varioram car will not work properly cutting power. This can also cause a rather large vacuum leak and may influence the availability of vacuum when actuated, vacuum needed for other functions related to the engine to work properly.

I checked one of the now 23 Plus-year-old diaphragm style actuators by disconnecting it, attaching a short length of vacuum hose to it, and sucking on the hose by mouth, lots of air drawn, but no movement. Interestingly what seemed to be a rather large vacuum leak through the actuator did not throw an OBD code on my car.

- One for on the top left side of the engine intake manifold;

- One that is part of the HVAC system and is connected to the lower left engine compartment heater blower ductwork;

- One on the left side underneath the Varioram intake manifold, and;

- The fourth actuator is on the top right side of the intake manifold, similar to the others but with a longer actuating arm.

A fifth actuator that can cause a power loss is located behind the Climate Control Unit (CCU) in the dash connected to a ventilation flap. This actuator is not present or may be present but disabled on early production 1995 model year and earlier cars.

The actuator is a piston-style one and looks to be rather robust. Porsche sells it as a complete vent unit but I bet, if leaking, an inexpensive metal can-style actuator purchased on eBay could be MacGyvered to replace it at a low cost. I tested mine by pulling the CCU clear of the dash w/o disconnecting the CCU harness then attaching a hose directly to the actuator and drawing a vacuum by mouth. Once a static vacuum was applied its pushrod stayed retracted so I could infer that it was not leaking. Interestingly the actuator’s pushrod had become detached from the vent mechanism, a very common situation. I replaced the missing pin with a tie wrap, which is probably good for at least another five years. Once reconnected to its vacuum source, I started the engine and actuated the vent flap by pressing the recirculating air button on the CCU while observing it through the dash hole. I then buttoned things up and was good to go, taking all of ten minutes.

It is quite easy to test the actuators including the Varioram system on so-equipped cars, all the actuators, and the solenoid valves that control them you will need a helper:

1. Have your helper start the engine and run it for a few moments, to build a vacuum;

2. Shuts the ignition off;

3. Turns the ignition back on without starting the engine while you observe the engine;

4. Observe the three Varioram actuators on the engine going through initial cycling, you will need a flashlight and push down on the rubber duct attached to the fan housing to observe the third actuator underneath the intake manifold;

5. For late build 1995 to 1998 cars with air conditioning press the air recirculate button on the Climate Control Unit(CCU) while the ignition is in the on position;

6. Listen for the kerchunk sound of the vacuum-actuated recirculating air flap moving behind the dash; 1994 and early 1995 cars may not have this vacuum actuator present. If you do not hear the sound and are not sure if your car has the actuator function just pull the CCU partway out of the dash and look behind it with a flashlight for the little plastic barrel-shaped actuator. If not present your car does not have one if present but the arm attaching it to the vent mechanism is missing and the actuator has no hose attached to it your car has the updated vent mechanism that has been backdated with the actuator detached to work on your car without the actuator function.

7. Go back behind the car and observe the heater flap actuator located on the ductwork on the lower left side of the engine;

8. Cycle the CCU thermostat setting from cold to hot and back to cold a few times while observing the actuator;

9. Observe the actuator retracting rotating the flap arm from the 7:00 o’clock (heat) to the 9:00 o’clock (cool air) positions as you rotate the knob on the CCU.

It is probably a good idea to run the above test any time you notice an operating change with the engine.

Improperly sequenced wires attached to the distributors:

https://edelweiss.smugmug.com/Cars/Porsche-Technical-Stuff/Beru-Ignition-Cables/

and how to make a quick diagnosis of it, or at least rule it out as a source of poor running:

If your 993 is a '96 or later, consider using an OBDII scanner to monitor the long & short-term fuel trims. This can provide insight into your fuel mixture, which should help you diagnose fuel delivery, for example,. fuel pressure, injectors, MAF sensor, as the root cause of poor running:.

- The long-term trim should be very close to zero percent;

- The short-term trim should fluctuate in small increments around zero percent.

- The before CAT O2 sensors' output should be varying from about .35 volts to about .65 volts.

- Clear the OBD code and see if it returns, then;

- If it does;

- Clean the Idle valve;

- If the car had the ignition serviced recently check the wire routing sequence to the plugs;

- Check that both distributor caps are not loose or have an ignition wire that is not fully seated.

- Check both distributor's coils by unplugging each center wire individually and restarting the car to see if the engine runs at all on just one for each. This will also verify the distributor belt is in place.

- Check the inside of the distributor caps, if visible carbon trails around the inside of the caps or heavy carbon on the rotor tip replace or clean the caps and rotors.

If any of the above look suspect address the issue. Then in any case then clear the code and see if it returns.

- If the code returns:

- Consider replacing the one ignition wire.

- Then remove and inspect the one sparkplug. It should be lightly ashed. If wet with fuel investigate the fuel injector and have the injector cleaned or replaced.

- If wet with oil clean it off with carb cleaner reinstall it and verify the oil is not overfilled. Overfilling is quite common.

- Clear the code that has returned and see if it returns again

#Varioram #Vacuum #PoorRunning #Actuators #MAF #AirFlowSensor #fuelPressure, # injector